Aluminum Tubular Busbar

Author:Frank Time:2023-05-05

Our company's main business: aluminum alloy tubular busbar, Conductive aluminum tube, ALUMINIUM PIPE BUS, 6063 (6063G) aluminum-magnesium alloy pipe busbar, LF-21Y (3A21) aluminum-manganese alloy pipe busbar, LDRE (6R05) aluminum-magnesium-silicon alloy Tube busbar, 6Z63 heat-resistant aluminum alloy tube busbar; insulated tubular busbar

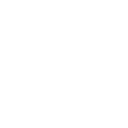

What is aluminium tubular busbar?

The aluminium tubular busbar is mainly used in the conductor connection between the power grid transmission wire and the substation transformer in the power construction project of our country, the jumper in the transmission line, the connecting conductor in the power equipment and the overcurrent conductor in the high current DC ice melting device. It is a new conductor that replaces the traditional rectangular, slotted, rod-shaped busbars and flexible conductors. It is one of the key equipment (materials) in the power transmission and transformation system. It plays a crucial role in the safe and reliable operation of the power transmission and transformation system and power equipment.

what is the aluminium tubular busbar

What type of alloy is used in Aluminium Busbar Tube ?

1060 high-purity aluminum tube

1060 aluminum pipe has high plasticity, corrosion resistance, good electrical conductivity and thermal conductivity; it can accept contact welding and gas welding. Use its advantages to manufacture some structural parts with specific properties, which are widely used in products that do not require high strength. Products are commonly used in signboards, billboards, building exterior decoration, lamp sockets, fan blades, electronic parts

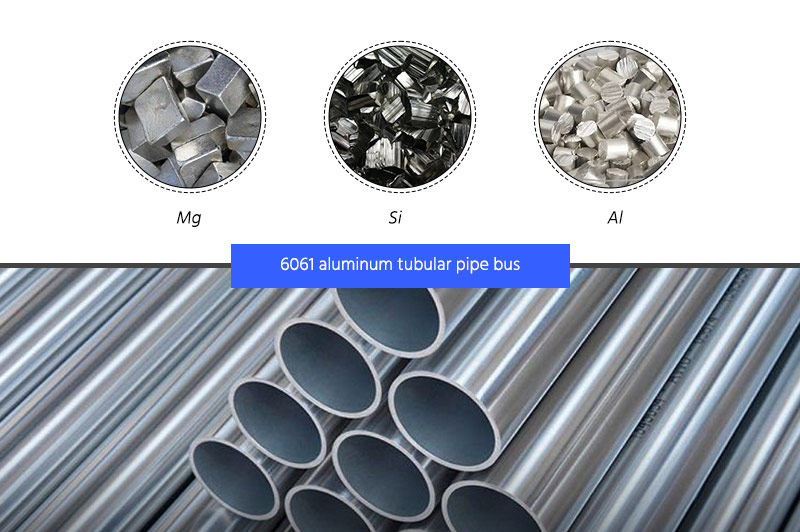

6061 ALUMINIUM TUBULAR PIPE BUS

supply status: T6, T651, H112, O... Extrusion tube: outer diameter Φ10mm~350mm

Ordinary hard aluminum alloy, good machinability, with medium strength

The main alloying elements of 6061 alloy are magnesium and silicon, and form the Mg2Si phase. If it contains a certain amount of manganese and chromium, it can neutralize the bad effects of iron; sometimes a small amount of copper or zinc is added to improve the strength of the alloy without significantly reducing its corrosion resistance; there is still a small amount of conductive material. copper to offset the influence of titanium and iron on electrical conductivity; zirconium or titanium can refine grains and control recrystallization structure; for machinability, lead and bismuth can be added. Mg2Si is solid-dissolved in aluminum, which makes the alloy have artificial aging hardening function.

6061 aluminium tubular bus bar

6063-T6 aluminum magnesium alloy tube busbar

This series of products has unique material properties (LDRE rare-earth aluminum alloy, 6Z63 heat-resistant aluminum alloy, etc.), is a new type of energy-saving busbar conductive material, and is a substitute for traditional steel-cored aluminum stranded wire, grooved, and rectangular aluminum busbars. , The product is a hollow tubular structure, with glossy surface, beautiful appearance and uniform size. The outer diameter is from φ60mm to φ300mm; the wall thickness is from 3mm to 12mm, and the length of a single piece can be up to 15 meters.

6Z63 High Strength Heat Resistant Aluminum Alloy Tubular Busbar

It can operate safely in the environment of 150°C-200°C, and at 250°C, the tensile strength can be maintained above 88% at normal temperature. This feature is suitable for ice melting device engineering and large-capacity substation engineering.

6101 Conductive Aluminum Tube

6101 aluminum alloy, American deformed aluminum and aluminum alloy. 6101 aluminum alloy high-strength conductive material. 55% IACS guarantee, good corrosion resistance and weldability, used for processing high-strength busbar conductors.

Conductive aluminum tube technical requirements

1) The nozzle is flat and perpendicular to the axis. 2) The length deviation of the pipe busbar is positive error: +15~+25mm 3) The pipe busbar is allowed to have straightening spiral marks that do not affect the outer diameter size, and its depth does not exceed 0.5mm 4) The pipe busbar bending degree: m/L<2.0 mm 5) The distance between the pipe mother and its matching liner is not more than 0.5mm and can ensure the installation needs. 6) The surface of the bus bar is smooth and smooth, without cracks, wrinkles, inclusions, deformation and distortion. 7) Elastic modulus value to control the deflection value after installation within the specified range. Aluminum alloy tube busbar model and current carrying capacity (when the ambient temperature is 20°C)

ALUMINIUM PIPE BUS specification options

The advantages realised by using aluminium tubular busbars are:

Busbars are lighter in weight and have a greater stiffness than stranded conductors with the same current transfercapacity.

This facilitates larger free spans;

Which require fewer points of supports and foundations;

impose a lower mechanical load on the foundation points and circuit equipment than stranded cables do under short circuitconditions;

are good electrical conductors due to the skin effect: the busbar surface has a current density that is relatively lower thanthat of a stranded conductor;

are permanently corrosion resistant;

possess excellent electric conductance properties;

have a smooth surface;

maintenance free;

Advantages of aluminum tubular bus

Advantages of aluminum tubular bus

1) The tubular conductor (busbar) adopts a series of advanced technologies such as domestic advanced hot top casting seamless tube, with smooth surface, high dimensional accuracy, high tensile strength, and is not easy to produce discharge and deformation;

2) The products are made of rare earth and heat-resistant aluminum alloy materials developed by the company (the national invention has been declared), which has excellent processing, welding, electrical conductivity and heat resistance properties. The products have been identified by the scientific and technological departments and have reached the international advanced level;

3) Good convection heat dissipation conditions, low temperature rise, low loss, strong electrical conductivity and large current carrying capacity;

4) High heat resistance, which can improve the working temperature of the tube busbar (working temperature reaches 150℃-200℃), the conductor has high mechanical strength at high temperature, and improves the safety and reliability of the power transmission and transformation system;

5) The installation area is small, and the combined pipe bus is 1/3 of the area of the flexible conductor;

6) Corrosion resistance, not easy to be covered with ice, strong disaster resistance, long service life (the first application in ice melting device in China);

7) Easy installation, beautiful appearance, safe, stable and reliable operation, easy to repair and maintain.

Why choose Signi aluminum as aluminium tubular busbar manufacturer & supplier

1.More than 12 years of experience in Conductive aluminum tube manufacturing, inventory and supply

2.Best price for aluminum tubular busbar - available worldwide with shortest delivery time

why choose us

3.Exporting ALUMINIUM PIPE BUS in compliance with ASTM, EN standards is our specialty

4.We can handle the logistics for you - we can provide FOB, CIF delivery to any port

5.The documents we provide include – Certificate of Origin, Chamber of Commerce certified invoice and PL, Test certificate according to EN 10204 3.1, other test reports as our customers may request.